R&D quality control

Juhonkia fully use SolidWorks software as the enterprise's R&D platform, build digital prototypes with mechatronic design, and perform mechanical structure simulation and fluid heat-dissipation simulation with the digital prototypes, which may improve comprehensively the R&D strength and realize the full 3D product design.

For our distribution network equipment, the quality control brain includes testing items such as power frequency withstand voltage test. Lightning impact test, partial discharge test, mechanical life test, temperature rise test, salt spray test, high and low temperature test and circuit resistance test to meet the requirements for the Class B spot-checking testing items of the up to 72.5kV inflatable cabinets, ring main units, prefabricated substations, HV and LV equipment assemblies and accommodate the testing items for material tensile test, analysis of metal contents of plates, and hardness testing, etc.

We will continue to focus on technological innovation and development. We are rated as an enterprise of patent demonstration of Hangzhou. At present, we have 13 software copyrights, more than 80 patents; 19 products passing certification of the provincial-level industrial new products, 4 products winning the second prize of new products of the Industry Association of Zhejiang Province, 2 products winning the Outstanding Industrial Products Award of Zhejiang Province, and 2 products winning the third prize of Machinery Industry Science and Technology of Zhejiang Province.

The R&D center surmounts difficulties, works hard and well, realizes significant economic returns and social benefits in the application of scientific and technological advances, helps us purse sustainable high-quality development, and becomes a model supporting the development of enterprise with technological innovation. The R & D center was awarded the title of "Workers' Vanguard" and "Innovation Studio for Highly Skilled Talents” of Hangzhou, and awarded "Model Collective" in May 2022 and ''Workers' Vanguard of Zhejiang Province" in March 2023.

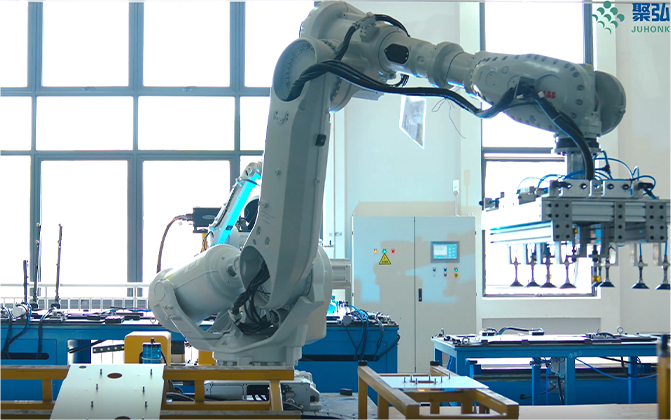

In December 2021, we updated the technological transformation into smart factory and digital workshop. Combining the "loT +" "Big Data and "Artificial lntelligence +" technologies, we realized full coverage of six "new scenario" applications including digital design, intelligent production, networked collaboration, shared manufacturing, personalized customization, and service extension. We established fully digital sheet metal manufacturing production lines, intelligent inflatable ring main unit assembling and fully automatic welding robot production lines. With digital twin platform integrated with MES, ERP and other systems, we achieved the meticulous management and control of the production equipment, materials, personnel processes, energy, and environment, and deep perception of the overall trend of business operation. As a result, the full life cycle of our products can be effectively controlled. Our internationally leading equipment, 6S production management system and large-scale production strength can ensure the high quality and stable performance of our products!